Our Craftsmanship: Creating Designs That Last

- 2 min read

Get a behind-the-scenes look at our BuzziSpace manufacturing facility where craftsmanship and passion for design drive our team on a daily basis.

Located across the Belgian border in Bladel, the Netherlands is our manufacturing facility, which houses over 80 employees spanned across different departments, including foam cutting, stitching, and upholstering. It is here that ideas are turned into reality, and innovation and imagination are nurtured.

With over 100 years of combined expertise, our hardworking team pieces together our celebrated acoustic solutions, lighting, and furniture with an eye for detail and great precision daily.

History

The facility was previously owned by a manufacturer of caravan cushions, while many of its employees were retained for their high level of expertise in upholstery and foam work, both of which are fundamental to creating our hero BuzziSpace products. Now take a look below to see what it has become!

Foam Cutting

Making a product like BuzziCube 3D involves a complex lamination process. Our skilled craftsmen need to find the perfect balance between temperature, glue, and pressure to seamlessly fasten the fabric to the precision-cut 3D foam. Every time we add new fabric to our offerings, our production team needs to reevaluate this process from scratch to ensure we are continuously progressing and innovating to meet our challenges.

Did you know, one block of foam can produce 55 BuzziCubes or 420 BuzziTiles?

Upholstery and Lacing

The common thread: an eye for detail

At BuzziSpace, craftsmanship is crucial in guaranteeing high-quality finished products. In several departments, much of the work is still done by hand, requiring special techniques to achieve the desired result. For instance, lacing and upholstery are just a few of the departments that necessitates a steady hand and eye for detail. The result is a product that is both functional and a work of art.

Felt Cutting and Stitching

Stitching is also a signature detail of ours along with our fabric cutting. Did you know it takes 66 minutes to cut out a BuzziFalls Alhambra? Our manufactury uses a CNC machine, which emits 18,000 ultrasonic vibrations per second, to help with the process.

Did you know it takes 66 minutes to cut out a BuzziFalls Alhambra?

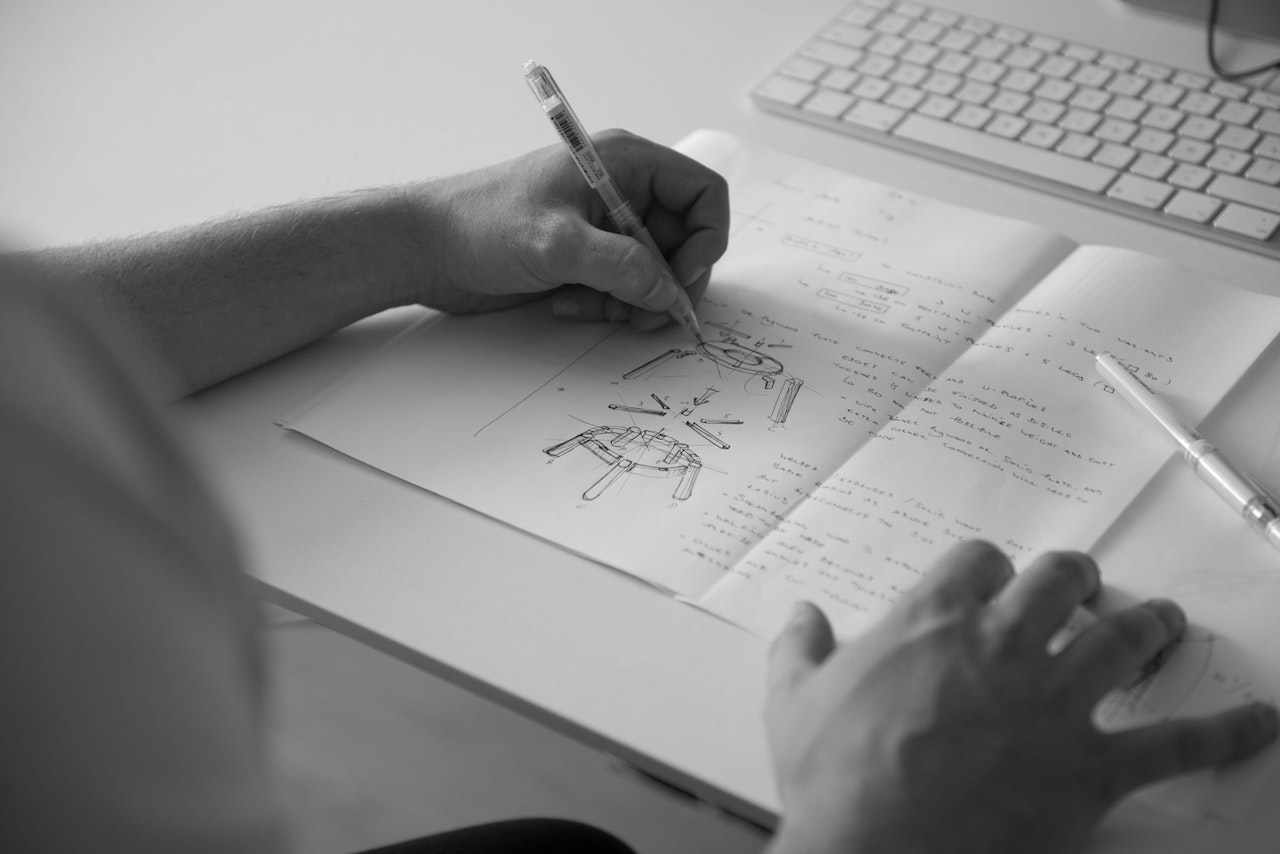

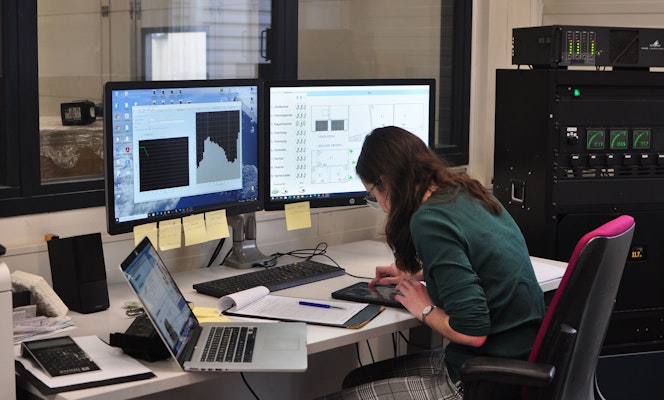

Discover BuzziMoon’s Design Journey

To round things up, let's take a look at the full design journey for our acoustic lighting solution, BuzziMoon. As you can see, our shared passion for creating products that will solve the modern design challenges of today, and beyond, keeps us striving for more.

Sign up for our mailing list

Related articles

8 Solutions for Privacy While Creating a Sense of Togetherness

Easily create an island of calm in an open-plan office with our sound-absorbing privacy booths, perfect for private calls, virtual meetings, temporary focus work, and more.

Color Revelations: Milan Design Week

Discover how to create a sense of togetherness with our color palette.

How to Elevate Your 4-Person Meeting Rooms Using Acoustic Solutions

Discover how sound-absorbing solutions can transform a workspace from poor acoustics and high noise levels to a comfortable and productive environment.

Color Revelations: The Hub

Use earthly tones to inspire feelings of wellness and serenity.